Wow. Just wow.

There weren’t many of these made (501 gobally), even fewer in right hand drive (75). We’re told that only 3 made it to Australia!

This is another one where the condition of the car was really very poor. Apparently in its former life, it lived on a dairy farm in rural Victoria – complete with a 1km dirt driveway!

It’s great that the current owner wants to get it back to looking the best it can. Lots and lots of hand polishing was the call for this job, around 22hrs by hand all up with most of the car needing 3-4 passes by hand. There was over 35hrs of work in the whole job.

The original plan was to finish off with Final Inspection’s Dark Matter, a high glazing wax. It doesn’t offer the durability or protection that FMJPP can, but it brings a certain extra glow to these reds in particular that you just can’t get from FMJ. After numerous discussions with the owner, who is interested in protecting the finish as best as possible whilst minimising the chance of inducing further swirls to the paint, we are going to be applying 2 coats of FMJPP for protection & durability, then layering up with Dark Matter to bring out that desired extra gloss.

The photos here are after one layer of FMJPP, the subsequent layers and DM will be performed over the next few weeks.

Here is the same, uncorrected panel under the sodium lighting in the workshop. The sodium lights are good, but it can be easy to miss smaller details, so supplementary lighting (such as speedlights or inspection torches like the FI Lucian) is essential to check your work.

Two passes of CAP Heavy using the Velvet Revolver shows that the desired finish isn’t too far away. If only the whole car could be done by machine…

Here is how we are protecting the edges. The panel on the left was just worked and the tape moved. Now it’s time to work the panel on the right. This prevents any stray strike-through on those delicate edges that are paper thin (remember, no clearcoat on this one)

There was lots of traces all over the car of previous “detailers” work. Plenty of polish stuck in various crevices.

This polish was actually removed by polishing by hand over the old… Then cleaning up properly.

As you can see, even in areas that we are working by hand, the edges of neighbouring panels/rubbers/trims all get masked up.

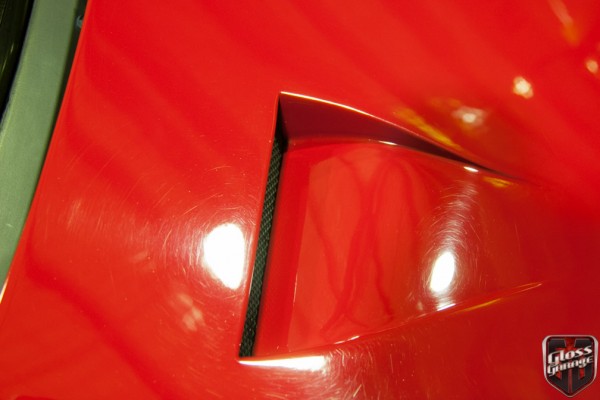

Here we are using a Nanofibre Paintwork Cloth to protect the door skin from the slat. The slat sits approximately 1-2mm clear of the door skin, but any agitation by polishing (even by hand) is enough to flex the slat and cause rubbing on the door skin.

Here’s the difference of two panels side-by-side. It’s easy to see the difference in finish and the depth of gloss is very clear.

The uncorrected panel on the right has so many imperfections that the light dispersion is causing the panel to take on an orange appearance.

You must be logged in to post a comment.